For Operations Visibility

Highly

Scalable

Distributed Architecture

Introducing Trinity Touch’s SolarVision™ SCADA is a reliable efficent and secured way for monitoring of utility scale solar power plants powered by latest IOT based hardware . It is essential to have a low cost SCADA to ensure real time performance monitoring , quick fault recognation and user defined control options to enhance the plant performance and maximum yield of PV power plant. The SolarVision™ SCADA provides flexibility in monitoring , controlling and analysing performance of various PV power plant components including trackers, inverters,energy meters and Weather equipments

Solar Vision™ is an efficient and cost effective tool designed for the monitoring of the performance resulting in lower downtime increasing the Plant’s overall profitability. Solar Vision™ is developed on the strong and proven Industry Software Platform which provide the flexibility to communicate with the Field controllers via OPC. The software in the control center with all the necessary Data via a TCP/IP network. In this way plant data is available for long term analysis over the service life of the PV Plant. Client access of the data of the SQL Server database insuring no data loss if there is a communication loss between remote clients. Graphical Interface of Solar Vision™ satisfy the requirement of Investors / Operator / Service Engineer.

Solar Vision™ system detects and logs any problem and triggers alarms so that the Operations team can fix or change components or fine-tune the process of plant operation. The system monitors the performance by means of a sophisticated mathematical model initialized once at installation time with some plant design data: PV panels peak power, inverters, manufacturer-provided electric parameters, number of strings, strings length, etc. The model is then continuously fed with local weather data and calculates in real-time what would be the correct energy production at 100% of plant capacity

Highlights of Solar Vision™ SCADA

- Complex data analysis & report generation through State of Art Software.

- Complied to IEC 61724 Photovoltaic System Performance Monitoring.

- Highly scalable and distributed architecture.

- Remote access by web navigator or web server.

- Server redundancy to access multiple clients.

- Email and SMS alert’s.

- Vendor Independent monitoring with support to Open Protocols.

- SLDC connectivity over IEC-60870-101/104.

- Support to substation SCADA Integration on IEC61850 Protocols

- Supports Centralized Monitoring with multiple options for data transfer.

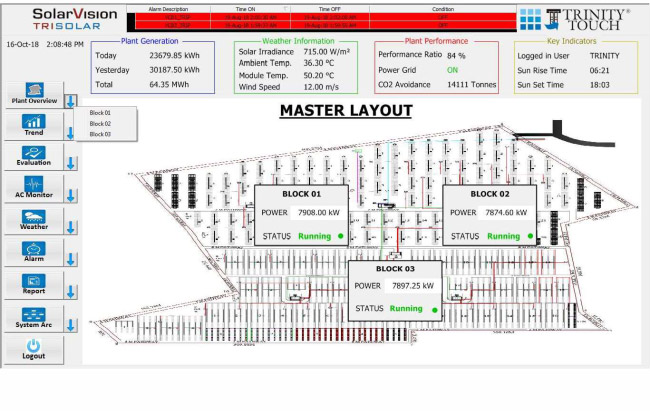

Plant at a glance

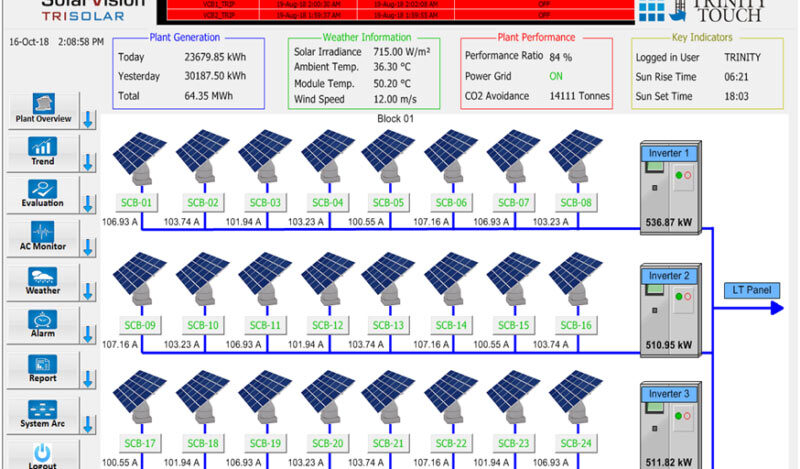

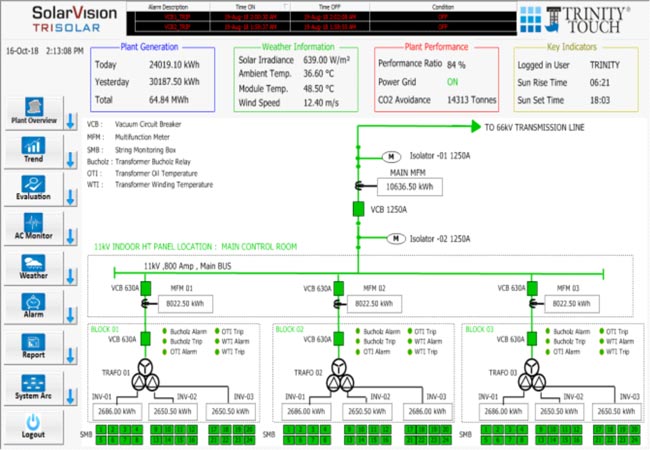

Solar Vision™ visualizes entire plant, blocks, inverter’s & string monitoring boxes on DC Side and Energy meters, Transformers and breakers at AC side including the associated detail information:

- The plant view shows the block wise separation with overviews of blocks. Trends and alarms for the plant.

- The block view shows the SMB, Inverter and LT panel details.

- Energy and power measurements and power quality analysis from power meters.

- In the static screen important parameter are displayed e.g. Energy generation, PR, Meteorological data .

- SLD provides real time data display and a high-level overview of the system with key plant performance indicators including daily power generation, instantaneous generation, tracker status, irradiance and expected generation etc.

- The detail information of devices are displayed in a form

of Pop-UP’s - Independent pages for Trends, Alarms, Events logging.

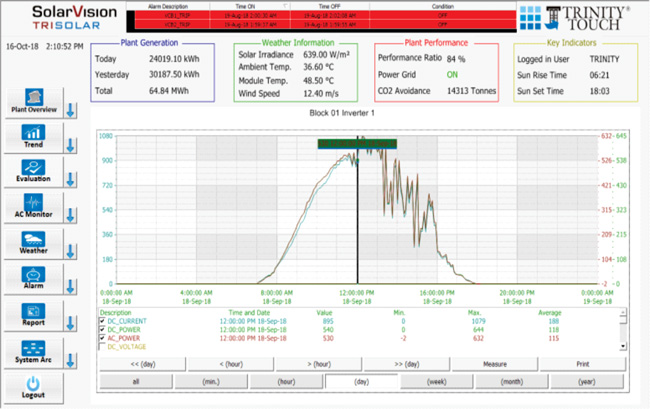

Solar Vision™provides the plant & block analysis for important meteorological data vs plant and block performance

- Irradiance / Generation

- Temp / Generation

- Simulated / Actual

- PR / Generation

- Real-time / Historical data

- A graphical comparative analysis and individual string alarms make it easy to identify low string performance or degradation issues

Addition to this user can trend as many points as desired with zoom function and further analyze the data over any user-defined time period

Solar Vision™ provides advanced optional features to meet the need of modern day transmission and distribution

Advanced optional features

- 1.Closed-loop control of active and reactive power

- 2.Hybrid Power management system

- 3. SLDC Connectivity with IEC 60870-1-101/104 Protocols

- 4. Data transfer on FTP to remote servers

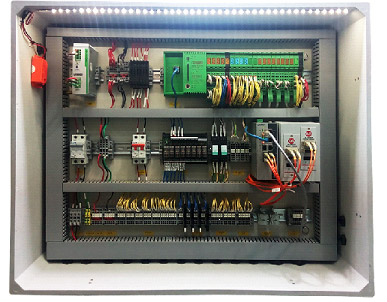

Hardware

Features at Glance

- Modular Architecture.

- Rugged PLC based data collectors.

- Flexible and Easy Programming tool complied to IEC 61131.

- Built in data logging facility in PLC with Support up to 2 GB External SD Card.

- Web enabled CPU.

- Redundant network connectivity.

- Built in Advanced Solar Library.

- Support for FTP.

- In built facility for SMS & E-mail alerts.

- Easy Spare availability.

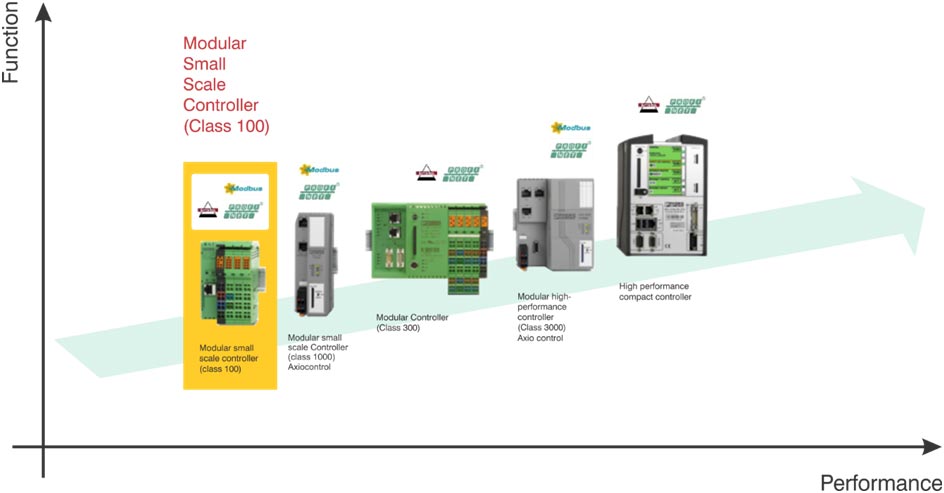

Overview of the Controllers

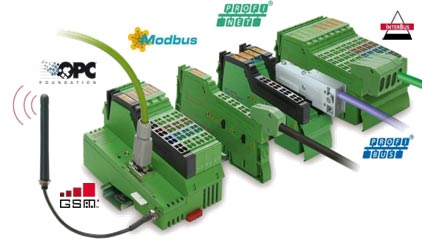

Best in communication

![]() Modbus TCP/Serial

Modbus TCP/Serial

![]() OPC DA/UA

OPC DA/UA

![]() IEC 61850

IEC 61850

![]() IEC 60870-5-104

IEC 60870-5-104

![]() Profinet

Profinet

![]() GPRS *

GPRS *

![]() FTP

FTP

![]() http

http

![]() SNTP

SNTP

![]() SMTP

SMTP

![]() SNMP

SNMP

![]() SQL

SQL

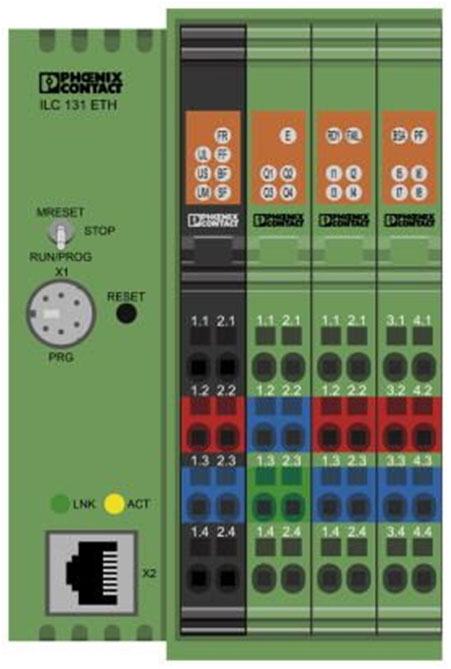

ILC 131 ETH

![]() Interfaces:Ethernet (10/100),Inline,RS-232 (MiniDIN)

Interfaces:Ethernet (10/100),Inline,RS-232 (MiniDIN)

![]() Processing speed < 1,7 ms/1k instructions

Processing speed < 1,7 ms/1k instructions

![]() Programm memory 192 kByte

Programm memory 192 kByte

![]() Data memory 192 kByte

Data memory 192 kByte

![]() Remanent data memory min. 8 kByte

Remanent data memory min. 8 kByte

![]() Internal parameterization memory with file-system (4 MByte)

Internal parameterization memory with file-system (4 MByte)

![]() No remote bus switch (max. 63 local participants)

No remote bus switch (max. 63 local participants)

![]() Onboard I/O (8/4)

Onboard I/O (8/4)

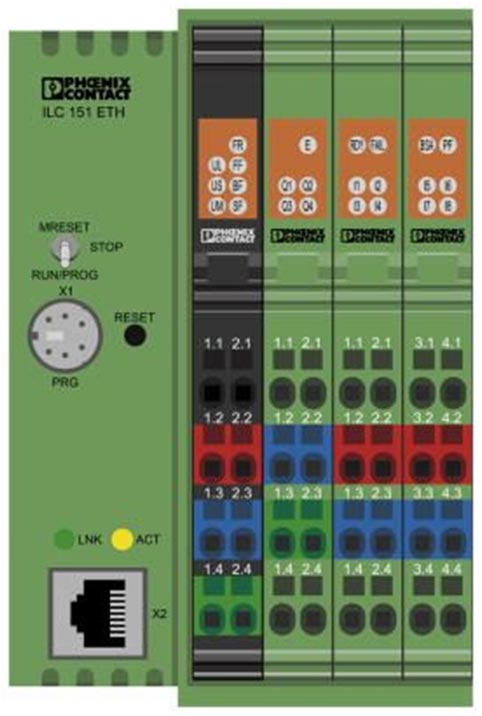

ILC 151 ETH

![]() Interfaces: Ethernet (10/100), Inline, RS-232 (MiniDIN)

Interfaces: Ethernet (10/100), Inline, RS-232 (MiniDIN)

![]() Processing speed < 1,5 ms/1k instructions, Inline, RS-232 (MiniDIN)

Processing speed < 1,5 ms/1k instructions, Inline, RS-232 (MiniDIN)

![]() Programm memory 256 kByte

Programm memory 256 kByte

![]() Data memory 256 kByte

Data memory 256 kByte

![]() Remanent data memory min. 8 kByte

Remanent data memory min. 8 kByte

![]() Internal parameterization memory with file-system (4 MByte)

Internal parameterization memory with file-system (4 MByte)

![]() Onboard I/O (8/4)

Onboard I/O (8/4)

ILC 151 ETH GSM/GPRS

![]() Interfaces: Ethernet (10/100), Inline

Interfaces: Ethernet (10/100), Inline

![]() Processing speed < 1,5 ms/1k instructions

Processing speed < 1,5 ms/1k instructions

![]() Programm memory 512 kByte

Programm memory 512 kByte

![]() Data memory 512 kByte

Data memory 512 kByte

![]() Remanent data memory min. 48 kByte

Remanent data memory min. 48 kByte

![]() Internal parameterization memory with file-system (4 MByte)

Internal parameterization memory with file-system (4 MByte)

![]() Onboard I/O (16/4)

Onboard I/O (16/4)

![]() Integrated GSM/GPRS-modem

Integrated GSM/GPRS-modem

ILC 350 PN

![]() Interfaces: Ethernet (10/100), Inline

Interfaces: Ethernet (10/100), Inline

![]() PROFINET Controller/ Device

PROFINET Controller/ Device

![]() 0.7 ms/ 0.5 ms for 1k instructions

0.7 ms/ 0.5 ms for 1k instructions

![]() 0,75 MByte/ 1 MByte RAM for programming (> 63.000/ >85.000 instructions)

0,75 MByte/ 1 MByte RAM for programming (> 63.000/ >85.000 instructions)

![]() 1,5 MByte/ 2MByte RAM for data

1,5 MByte/ 2MByte RAM for data

![]() 64 kByte NVRAM for remanent data

64 kByte NVRAM for remanent data

![]() Exchangeable flash memory (for projects or own data)

Exchangeable flash memory (for projects or own data)

![]() Directly integrated inputs/outputs 12 I / 4 O

Directly integrated inputs/outputs 12 I / 4 O

![]() IEC 61131-3 and -5 via PC WORX

IEC 61131-3 and -5 via PC WORX

Client List for SCADA

EPC: TATA POWER SOLAR |

EPC: STERLING & WILSON |

EPC: VIKRAM SOLAR |

EPC:RENEW POWER |

EPC: SIEMENS GAMESA |

EPC: SIEMENS GAMESA |

EPC: VIKRAM SOLAR |

EPC: PREMIER SOLAR |

EPC: SWELECT |

EPC: BOSCH |

EPC:RENEW POWER |

EPC: BOSCH |

EPC: GREENKO |

EPC: PREMIER SOLAR |

EPC: KELTRON |

EPC: STERLING & WILSON |

EPC:ENRICH SOLAR |

EPC:UJAAS SOLAR |

EPC: STERLING & WILSON |

EPC: SIEMENS GAMESA |

EPC: SWELECT |

EPC: TATA POWER SOLAR |

EPC:TATA POWER SOLAR |

EPC: KELTRON |