Customised Basic 1308

|

|

| Size 130 x 80 x 60 (H x W x Dmm) |

Size 130 x 80 x 60 (H x W x Dmm) |

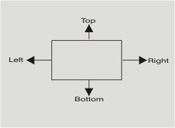

| Type | Left | Right | Top | Bottom | Total Quantity |  |

| PG 7 | 1 | 1 | 3 | 3 | 8 | |

| PG 9 | 1 | 1 | 3 | 3 | 8 | |

| PG 11 | 1 | 1 | 3 | 3 | 8 | |

| PG 13.5 | 1 | 1 | 2 | 2 | 6 | |

| PG 16 | 1 | 1 | 2 | 2 | 6 | |

| PG 21 | 1 | 1 | 2 | 2 | 6 | |

| M12 | 1 | 1 | 3 | 3 | 8 | |

| M16 | 1 | 1 | 3 | 3 | 8 | |

| M20 | 1 | 1 | 2 | 2 | 6 | |

| M25 | 1 | 1 | 2 | 2 | 6 |

| Type | Number | Wire Size mm | Amp.Rating |

| UT/ST 2.5 | 14 | 0.2-2.5 | 24 |

| UK 5N | 11 | 0.2-4 | 41 |

| UK6N | 8 | 0.2-6 | 57 |

| UK 10N | 7 | 0.5-10 | 76 |

| UK 16N | 5 | 4-10 | 101 |

| UIK 16N | 5 | 4-16 | 101 |

| Type | Max. Length for enclosure | Article No. |

| TDR2-35/7.5 Perforated | 110 mm | 011700271 |

| TDR2-15/5.5 Perforated | 110 mm | 011700254 |

| TDR3-35/7.5 Perforated | 110 mm | 011700283 |

| TDR3-15/5.5 Perforated | 110 mm | 011700279 |

| Current | Wire Size | |||

| Rail | Material | (A) | AWG | mm2 |

| 35/7.5 (Slotted) | Steel | 65 | 8 | 10 |

| 35/7.5 (Un Slotted) | Steel | 87 | 6 | 16 |

| 35/15 (Slotted) | Steel | 125 | 4 | 25 |

| 35/15 (Un Slotted) | Steel | 125 | 4 | 25 |

| 15/5.5 (Slotted) | Steel | 35 | 12 | 4 |

| 15/5.5 (Un Slotted) | Steel | 47 | 10 | 6 |

| Difference between TDR2 and TDR3 series DIN Rails | ||||

| S.No. | Properties | Unit | TDR2 | TDR3 |

| 1 | Tensile Strength | N/mm2 | 270 | 320 -410 |

| 2 | Elongation | N/mm2 | 28% | 30 -36% |

| 3 | Hardness | HRB | 50 | |

| 4 | Elastic Limit | N/mm2 | ———– | 230 -280 |

| 5 | SST stability Red Rust (Minimum) |

Hours | 240 | 350 |

• Mounting rails made of steel in accordance (DIN 60715) are available in Zinc plated and thick film trivalent chrome passivated. The base metal as steel used for DIN rails as per EN10130. Due to high mechanical strength & durability, high corrosion prohibitive plating and lead free (Confirms to RoHS compliance) provides the best solution for general applications.

• These rails are often used as grounding bars. The current carrying capacity of these rails and the copper wire sizes required to carry that current are given above.

• The 35/7.5 high rail is suitable for the majority of application and is the more cost effectiveness.

• When heavy components like large PLC’s, Transformers, MPCB’S, heavy contactors and relays has to be mount than 35/15 rail is more suitable.

• The 15/5.5 rail is more than half width of 35/7.5 is used for mounting of terminal blocks in confined spaces.

| 24,110,220,440 VAC (Dia 22.5mm) | 2 Nos |

| 24,110,220,440 VAC (Dia 30 mm) | 2 Nos |

| 12,24,48,110 VDC (Dia 22.5mm) | 2 Nos |

| 12,24,48,110 VDC (Dia 30 mm) | 2 Nos |

| Type | Number |

| 22.5 mm | 2 Nos |

| 30 mm | 2 Nos |

Ordering Data For Accessories

| Mounting Plate | Type | Article No. |  |

| Mounting Plate CRCA Sheet | Basic MP 1308 | 011700608 | |

| Thickness 1.5 mm | |||

| Zinc Plated | |||

| Mounting Clamp | Type | Article No. |  |

| Mounting Clamp CRCA Sheet | Basic MC 1308 | 011700609 | |

| Thickness 3 mm | |||

| Zinc Plated | |||

| Cover Screw | Article No. |  |

| Polyamide Grey Colour | 011700910 |

| Existing Customised Solutions Of Terminal Block Enclosure | |||||

| Description | Article No. | DIN Mounting Rail | Terminal Block | ||

| Type | Qty | Type | Qty | ||

| CS-ABS 1308-5-6 | 011700009 | TDR2-15/5,5 | 110 mm | MBK5 | 6 |

| CS-ABS 1308-5-5 | 011700008 | TDR2-15/5,5 | 110 mm | MBK5 | 5 |

| CS-ABS 1308-6-2.5R | 011700159 | TDR2-35/7,5 | 110 mm | UK 2.5 | 6 |

| CS-ABS 1308-2.5-4 | 011700184 | TDR2-35/7,5 | 110 mm | UK 2.5 | 4 |

| CS-ABS 1308-3-6 | 011700002 | TDR2-15/5,5 | 110 mm | MBK3 | 6 |

| CS-ABS 1308-MBK 3X6 | 011700240 | TDR2-15/5,5 | 110 mm | MBK3 | 6 |

| CS-ABS 1308-UK 2.5X8 | 011700251 | TDR2-35/7,5 | 110 mm | UK 2.5 | 8 |

| Existing Customised Solutions of Terminal Block Enclosure with Cable Gland | |||||||

| Description | Article No. | DIN Mounting Rail | Terminal Block | Cable Gland | |||

| CS-ABS 1308-UK 2.5X8-4G | 011700260 | TDR2-35/7,5 | 110 mm | UK 2.5 | 8 | PG-7 | 2 |

| PG-9 | 1 | ||||||

| PG-21 | 1 | ||||||

| CS-ABS 1308-EFP-030-422-001 | 011700111 | TDR2-35/7,5 | 110 mm | UK 2.5 | 2 | PG11-2 | 2 |

| CS-ABS 1308-UK2.5X10 -PG11X4 | 011700264 | TDR2-15/5,5 | 110 mm | MT 1.5 | 10 | PG11 | 4 |

| CS-ABS 1308-4X10 | 011700356 | TDR2-35/7,5 | 110 mm | UK4 | 10 | ||

| CS-ABS 1308-2.5X10-PG11X4 | 011700359 | TDR2-35/7,5 | 110 mm | UK 2.5 | 12 | PG11 | 4 |

| CS-ABS 1308-UK2.5X12 | 011700082 | TDR2-35/7,5 | 110 mm | UK 2.6 | 12 | ||

| CS-ABS 1308-UK2.5X8-PG11X2 | 011700087 | TDR2-35/7,5 | 110 mm | UK 2.7 | 8 | PG11 | 2 |